Big Results in a Small Footprint When You Automate with Dobot Palletizer

End-of-line packaging is often one of the most labor-intensive and ergonomically challenging parts of the production process. As companies seek smarter ways to boost throughput, reduce workplace strain, and improve reliability, palletizing has become an ideal candidate for automation, especially for operations looking to boost throughput and reduce workplace strain. Yet for many with limited floor space or variable product runs, traditional systems have felt out of reach. That’s where compact robotic solutions like the Dobot Palletizer are changing the equation.

Designed for Tight Spaces and Fast ROI

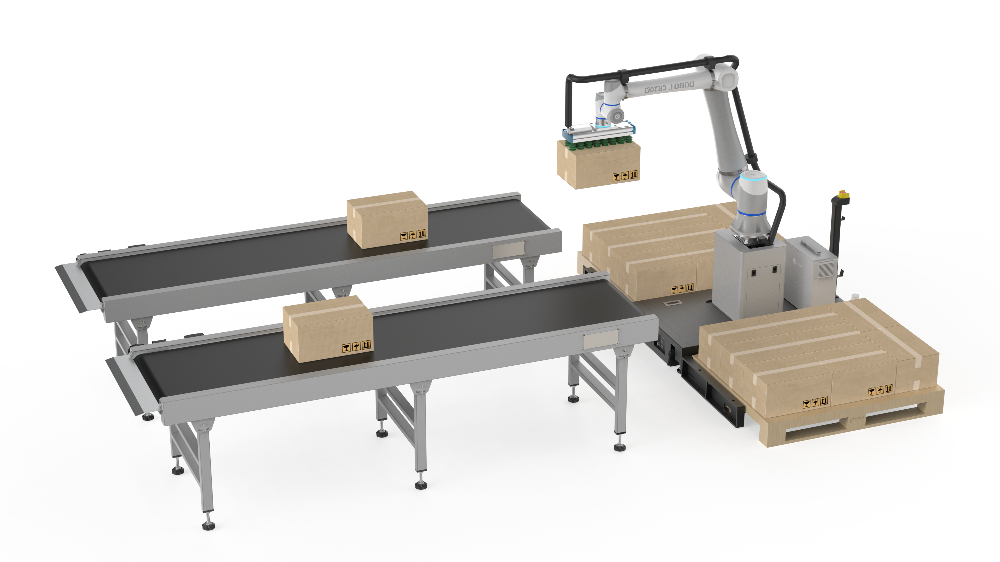

Unlike traditional, bulky palletizing systems that require significant reconfiguration, Dobot’s CR-series palletizers are engineered for compactness and easy integration. Their small footprint allows them to fit into existing packaging lines without the need to rework your entire layout.

These systems are especially well-suited for mid-sized manufacturers, co-packers, and fulfillment centers that want to reduce manual labor and improve throughput—without the complexity and cost of traditional automation cells.

Installation is fast, and because the system is designed for modularity, many users can get up and running within a matter of days, not weeks.

Built-In Flexibility for Changing Needs

Today’s production environments demand adaptability. The Dobot Palletizer is designed with flexibility at its core and is capable of handling a variety of box sizes, pallet patterns, and stacking configurations. Whether you’re palletizing lightweight cartons or heavier cases up to 20 kg, the system can be easily reprogrammed to meet changing product or customer requirements.

The intuitive software interface allows operators to build and adjust pallet patterns without coding or extensive technical training. Changes can be made quickly between runs, making the system ideal for operations with multiple SKUs or seasonal demand shifts.

Safe and Ergonomic by Design

Manual palletizing is one of the most physically demanding tasks on the production floor—often leading to repetitive strain injuries, worker fatigue, and inconsistent results over time. Dobot palletizing systems are designed to address these challenges directly by taking over the heavy lifting and repetitive motion tasks.

The system features a collaborative robotic arm with built-in force limitations, allowing it to safely operate near human workers without full fencing in many setups. Additional safety measures such as light curtains or safety scanners can be integrated based on your specific requirements. The result is a safer, more ergonomic work environment—one where operators can shift their focus from physical labor to higher-value tasks like supervision and process improvement.

Scalable Automation That Grows With You

One of the key advantages of the Dobot Palletizer is its scalability. Whether you’re running a single shift or expanding to multiple production lines, the system is designed to grow alongside your business.

Its modular design allows you to start small, with a single arm and basic gripper, and add components like lifting columns, conveyors, or more advanced grippers as your needs evolve.

For facilities that anticipate growth, this means you can invest in automation today without boxing yourself into a rigid system. As throughput increases or product variety expands, your palletizing solution is ready to scale with you, delivering long-term value without costly overhauls.

A Cost-Effective Path to Automation

One of the biggest barriers to adopting automation has historically been cost. Traditional palletizers often come with high price tags and significant integration expenses. Dobot’s approach brings a more accessible entry point to automation.

With full system pricing well below that of conventional options, including robotic arm, base frame, vacuum gripper, and user-friendly interface, Dobot Palletizers deliver a faster return on investment. For operations struggling with labor shortages or rising fulfillment volumes, that ROI is often measured in months, not years.

See How Much You Can Save

Whether you’re shipping 10 pallets a day or 100, automating palletizing can improve efficiency, safety, and consistency across the board. Fuse Automation helps you evaluate, install, and support the right solution for your operation with the Dobot Palletizer. It’s a smarter, more scalable end-of-line strategy.

Schedule a Consultation with Fuse Automation today to see how much time, labor, and cost you can cut.